|

DEYU AGRICULTURE CORPORATION |

|

|

DEYU AGRICULTURE CORPORATION |

|

Company Overview

Company Overview

Operating Model

Operating Model

Mission & Philosophy

Mission & Philosophy

Strengths

Strengths

Facilities

Facilities

We are a vertically integrated producer, processor, marketer and distributor of organic and other agricultural products made from corn and grains operating in Shanxi Province in the People's Republic of China. Headquartered in Beijing, Deyu Agriculture Corp. (OTCBB: DEYU) operates in Jinzhong City and Quwo County of Shanxi Province.

Our mission is to develop, produce and deliver high quality food products that promote balanced diet and improve the health of our customers.

We have access of 20 years to over 109,000 acres of farmland in Shanxi Province for breeding, cultivating, processing, warehousing, and distributing corn and grain products. We have a nationwide sales network covering manufacturers, grain traders, wholesalers, distributors, institutional clients and retail stores in China. Our facilities include modern warehouses with storage capacity of over 100,000 tons and sophisticated production lines with annual production capacity of over 105,000 tons and 700,000 tons for grain products and corn, respectively.

A brief description of our products is set forth below, by division:

1.Corn Division - acquires unprocessed corn for value-added processing such as cleaning, drying packaging, etc. The main consumers for this division range from livestock feed companies to corn oil/corn starch manufacturing companies as well as governmental procurement agencies in China.

2. Grain Division - acquires unprocessed grains including millet, green bean, soy bean, black rice and many other varieties of grains traditionally grown and consumed in China for value-added processing such as peeling, cleaning, grinding, packaging, etc. The Grain Division also produces and distributes deep processed grain products, such as bean based products, fruit vinegars and juices, noodles and other grain products. We sell our processed grain products to wholesalers, distributors, institutional clients and directly to consumers in retail stores.

3. Bulk Trading Division - conducts bulk trading through procuring and wholesales of rice, flour, wheat, kidney beans, green beans and other agricultural products. The majority customers of this division include food manufacturers, grain trading companies, wholesalers and governmental procurement agencies in China.

OPERATING

MODEL

|

|

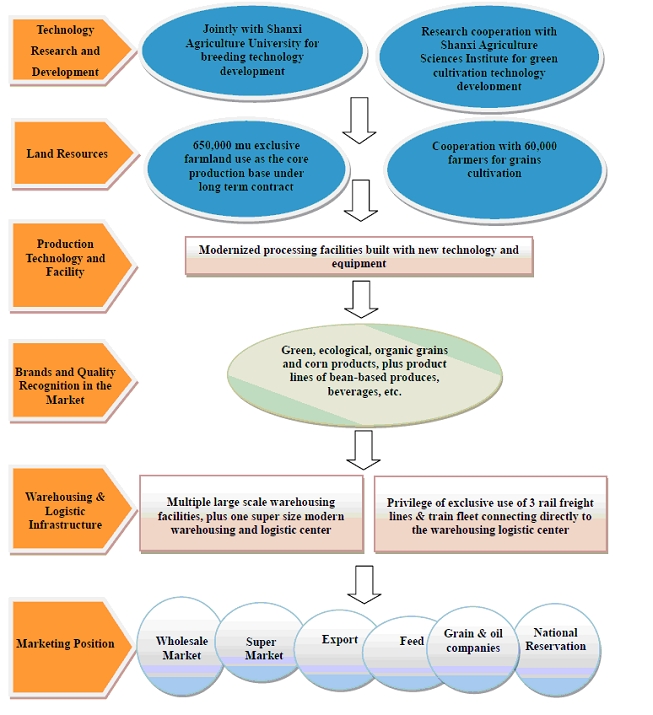

We have adopted the operating model of "ompany + Farmers + Cultivation Base,"which is well supported by our advanced production capabilities, large warehousing capacity and exclusive logistic centers. In Shanxi Province, we have access to over 109,000 acres (650,000 mu) of farmland that serves as our plantation base and we have established partnerships with over 60,000 farmers for the cultivation of high quality grains and corn. Based on our supply, the Company has developed the "Deyu"operating chain, which consists of breeding, cultivating, processing, warehousing and distribution of our products. The Company's operating model can be described as following:

|

MISSION

& PHILOSOHY

|

|

Mission

Philosophy |

STRENGTHS  |

|

R&D

Cultivation Base

Farmer Partnerships

Advanced Production Lines

Warehousing and Logistics

Honors and Awards |

FACILITIES

|

|

We maintain facilities in central and southern Shanxi Province with total site coverage of approximately 1,780,000 square feet (approximately 165,000 square meters) and constructed area of 500,000 square feet (approximately 46,000 square meters). Our facilities are equipped with advanced crop production, processing and packaging lines as well as modern equipment. Corn Production Capacity Our Corn Division - warehousing, processing and logistics center is located in Jinzhong with site coverage of 503,000 square feet (approximately 47,000 square meters) and constructed area of 144,000 square feet (approximately 13,000 square meters). The processing center has five drying cylinders and six warehouses for the storage of 70,000 tons. We have a large rental cave-type warehouse named Shanxi 661 Warehouse with storage capacity of 30,000 tons. We also have contracts for temporary warehouses near railway stations which supplement our storage capacity. Our total capacity of storage and annual turnover reach over 100,000 tons and 700,000 tons, respectively. We process drying and water removal treatments for corn before the corn is stored in our warehouses. The five drying cylinders are equipped with the most advanced equipment for corn drying. After the drying process, the corn is packaged in bags and moved into warehouses. Then, the products undergo insecticide and anti-bacterial treatments. After being sealed and air ventilated, the products are then stored in enclosed warehouses. Our six newly-constructed warehouses are equipped with advanced detection and air ventilation devices to ensure cereals are being kept in good condition. Ventilation ducts are installed on the ground level of the warehouses. Once moisture is detected, air ventilation driven by a blower will help disseminate the overall heat on the cereals. Infrared temperature sensors and 360-degree high resolution cameras have been installed in each warehouse to allow the control room to conduct 24-hour monitoring for real-time analysis of water, moisture, mildew and pests so that we can quickly take corrective measures. The cave-type warehouse that we rent is fully enclosed and have thermostatic and moisture proof characteristics. The cave-type warehouse is built with 1.5 meter thick walls and moisture proof layers. They maintain a temperature of 10 degrees Celsius throughout the year, which is well-suited for food storage. Since no air conditioning is required, the operating costs of these warehouses are low. These warehouses are also equipped with infrared sensors that can accurately detect temperature changes and the presence of rodents, insects and other pests. Grain Production Capacity We are equipped with three fully automatic production lines for millet, grain and flour at our Jinzhong production base in the center of Shanxi Province, with site coverage of approximately 199,000 square feet (approximately 18,000 square meters) and a constructed area of 119,000 square feet (approximately 11,000 square meters). These lines include various kinds of rice milling machines, filtering machines, elevators, color selection machines, exhaust fans, automatic packing machines and other equipment. The production capacity of grain is over 60,000 tons. Another production base in Quwo, in the southern part of Shanxi Province, has site coverage of over 1,076,000 square feet (approximately 100,000 square meters) and a constructed area of 238,000 square feet (approximately 22,000 square meters). This base is equipped with three kinds of advanced production lines: (1) two production lines for bean-based products with an annual production capacity of 15,000 tons; (2) two production lines for other grain products with an annual production capacity of over 26,000 tons; (3) two production lines for fruit vinegar and fruit juices with an annual production capacity of 4,000 tons. These production lines are comprised of advanced grain milling, degreasing, automatic drying, packaging, inspection and testing equipment. At present, less than one third of the land at this production base has been developed. We believe we can develop more production lines for future demand without acquiring land use rights for more land. To ensure high quality, we have installed fully automated production equipment at our facilities. Characteristics of our production lines and equipment are as follows:

Our modern equipment and technology, combined with advanced processing techniques, helps to ensure that grain production is high-quality, natural, green and ecological. Additionally, a portion of our grains can be categorized as organic by the Beijing Zhonglu Huaxia Organic Food Certification Centre. We believe the careful management of breeding, cultivation, production, packaging and storage also leads to high quality products. We implement strict quality control with each process in purchasing, storage, processing, packaging and distribution. We keep all items that are examined in the course of quality control inspections for one year in accordance with National Technology Quality Supervision Bureau requirements. We cooperate fully with the Bureau during their random testing and examination of our products. |